Rubber Cement Crafting Secrets: The Ultimate Comprehensive Guide

Rubber cement stands as a versatile adhesive in the realm of crafting, offering unique properties that make it a favorite among hobbyists and professionals alike. Whether you’re a seasoned crafter or new to the world of DIY projects, understanding the nuances of rubber cement can elevate the quality and longevity of your creations. This detailed guide provides an in-depth exploration of rubber cement, from its composition and applications to expert tips and troubleshooting advice. Let’s dive into the comprehensive secrets of rubber cement crafting.

Understanding Rubber Cement: The Core Elements-Rubber Cement Crafting Secrets

One kind of glue that is well-known for its strength, flexibility, and adaptability is rubber cement. Rubber cement, which keeps its pliability even after drying, is created when rubber polymers dissolve in volatile solvents. Rubber Cement Crafting Secrets: Because of this, it’s very helpful in a variety of crafting applications where adjustability and flexibility are essential.

Composition of Rubber Cement-Rubber Cement Crafting Secrets

The principal constituents of rubber cement are:

Rubber polymers: These can be natural rubber or synthetic variants like neoprene or styrene-butadiene. The rubber polymers are responsible for the adhesive properties of the cement, providing a strong yet flexible bond.

Volatile Solvents: Common solvents include acetone, hexane, or petroleum distillates. These solvents keep the rubber polymers in a liquid state, allowing for simple application. Upon application, the solvents evaporate, leaving a thin layer of rubber that adheres to surfaces.

Key Characteristics

Rubber cement is perfect for crafts since it has a number of noteworthy qualities.

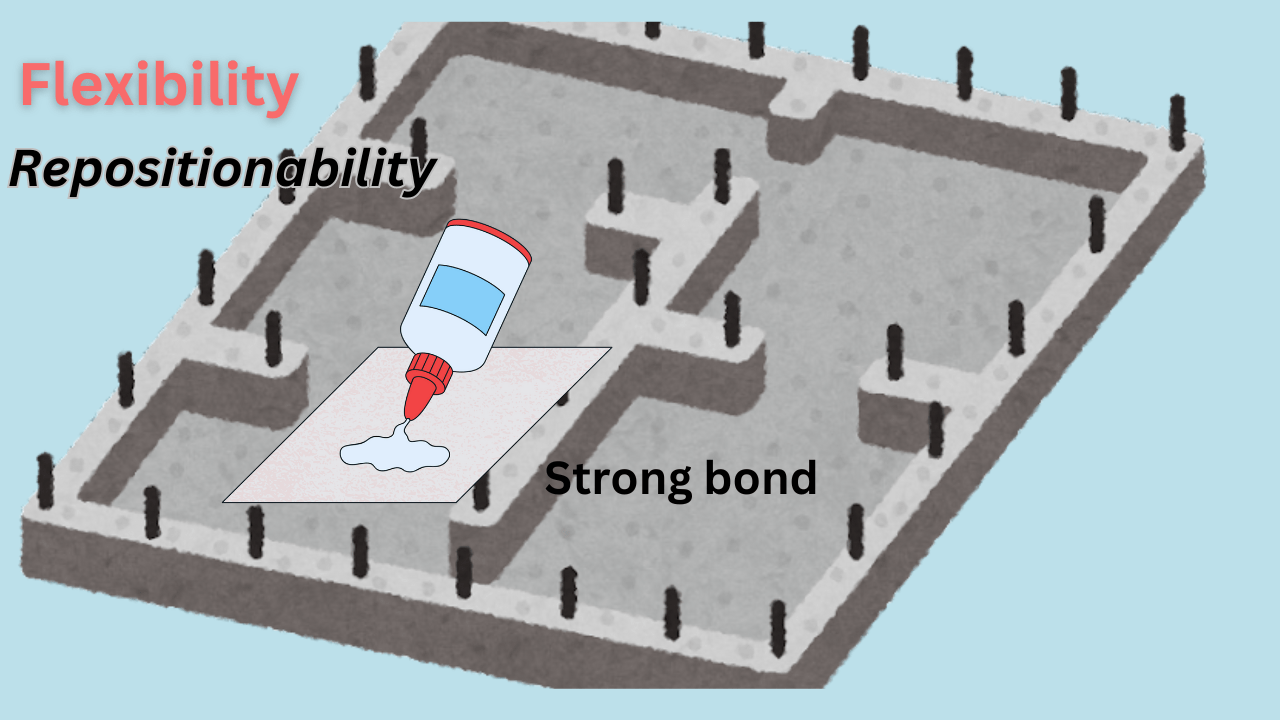

- Flexibility: Rubber cement’s primary advantage is its flexibility. After drying, it maintains a rubbery texture that can bend and stretch without breaking. This feature is particularly beneficial for projects that involve materials that need to move or flex.

- Repositionability: Rubber cement is unique in that it allows for materials to be repositioned before the adhesive sets completely. This trait is advantageous for intricate projects where precision is key.

- Non-permanent Bond: Rubber cement creates a strong bond that is removable from surfaces without causing damage. This makes rubber cement suitable for temporary applications or projects where changes might be necessary.

Rubber Cement Finds Diverse Applications in Crafting

Because of its adaptability, rubber cement may be used for a variety of crafts. Here are some prominent uses:

Paper Crafts: Rubber Cement Crafting Secrets

In the world of paper crafting, rubber cement is a staple. Rubber cement is an excellent choice due to its ability to bond paper without warping.

Scrapbooking: Rubber cement allows for precise placement of embellishments and photos, ensuring that they adhere securely without causing the paper to curl or buckle.

Card Making: Rubber cement provides a clean, strong bond that holds decorative elements in place when creating handmade cards.

Collage Work: Rubber cement gives you the flexibility to adjust and reposition paper pieces until you achieve the desired arrangement.

Photo Mounting

Photographers and scrapbookers often use rubber cement for mounting photos. The adhesive’s non-permanent nature allows for photos to be adjusted or repositioned on albums or displays. This is especially useful for:

Photo albums: Rubber cement holds photos securely while allowing for easy removal and repositioning.

Displays: Rubber cement holds photos in place for exhibitions or gallery displays, allowing for their eventual movement or replacement.

Model Building-Rubber Cement Crafting Secrets

Model builders find rubber cement invaluable for assembling models. Its flexibility ensures that the model maintains structural integrity while allowing for minor adjustments during the assembly process. It is particularly useful for:

Scale Models: Rubber cement helps to bond various scale models’ components without affecting their structural alignment.

Rubber cement provides a strong bond that remains flexible for plastic model kits, accommodating any slight adjustments needed during construction.

Textile Crafts

Although it is less common, textile crafts also use rubber cement. In certain applications, it can bond fabrics to other surfaces or even to itself. It is important to test rubber cement on a small fabric sample first to ensure it does not damage or discolor the material.

Expert Tips for Efficient Use of Rubber Cement

To maximize the effectiveness of rubber cement, consider the following expert tips:

Surface Preparation

Proper surface preparation is crucial for achieving a strong bond with rubber cement. Follow these steps:

Clean Surfaces: Make sure the surfaces that need bonding are clear of dust, grease, or moisture. Use a clean, dry cloth to wipe down the surfaces before applying the adhesive.

Before applying the rubber cement, make sure the surfaces are completely dry. Moisture can interfere with the adhesive’s ability to bond effectively.

Application Techniques

The application technique can greatly impact the performance of rubber cement. Follow these guidelines:

Apply Thin Layers: Use a brush or applicator designed for rubber cement to apply a thin, even layer to one surface. Avoid applying excessive amounts, as this can lead to longer drying times and a potential mess.

Allow to Dry: Let the rubber cement dry until it becomes tacky to the touch. This typically takes a few minutes. Press the surfaces together firmly once the adhesive reaches the tacky stage.

Pressure Application: To ensure that the surfaces adhere properly, apply consistent pressure. For best results, use a rolling pin or similar tool to press the surfaces together.

Storage and handling

Proper storage and handling of rubber cement are essential for maintaining its effectiveness.

Store Properly: Keep rubber cement in a cool, dry place. If the container seals improperly, the volatile solvents can evaporate, reducing the adhesive’s effectiveness.

Seal the Container: To keep the rubber cement from drying out, always make sure to tightly seal the container after use.

Thickening Cement: If the rubber cement becomes too thick, you can add a small amount of solvent to restore its original consistency. Follow the manufacturer’s instructions for solvent addition.

Troubleshooting Common Rubber Cement Issues

Even with careful use, you may encounter issues with rubber cement. Here’s how to address common problems:

Drying too slowly.

If rubber cement is drying slower than expected,

Check the humidity. High humidity can slow down the drying process. If possible, work in a well-ventilated area with low humidity.

Reduce Application: Applying too much rubber cement can extend drying times. Ensure you are using a thin, even layer.

Difficulty Removing

To remove rubber cement from surfaces:

Use a Rubber Cement Pick-Up: A rubber cement pick-up or eraser can help lift off the adhesive without damaging the surface.

Solvent Application: Apply acetone to the area for stubborn residues. Gently rub the surface to dissolve the adhesive.

Weak Bond

If the bond appears weak,

Reapply Cement: Ensure that you applied an even layer of rubber cement and allowed it to become tacky before bonding. If necessary, reapply and press the surfaces together.

Check Drying Time: Insufficient drying time can result in a weak bond. Prior to joining surfaces, ensure that the cement is tacky.

Safety precautions when using rubber cement

Safety is paramount when working with rubber cement. Follow these precautions to protect yourself and others:

Ventilation: To avoid inhaling fumes, use rubber cement in a well-ventilated area. If working indoors, consider using a fan or opening windows to improve airflow.

Protective Gear: Wear gloves and safety glasses to protect your skin and eyes from accidental contact with the cement.

Avoid Ingestion: Keep rubber cement away from children and pets. Avoid ingestion, as it can be harmful if swallowed.

The article discusses advanced techniques for crafting with rubber cement.

For those looking to push the boundaries of rubber cement use, here are some advanced techniques:

Layering for strength

You can use rubber cement in layering techniques to increase the strength and durability of your projects.

Layer Application: Apply multiple thin layers of rubber cement to one surface, allowing each layer to dry partially before adding the next. This can enhance the bond’s strength and flexibility.

Combine with Other Adhesives: For specific applications, you can use rubber cement in combination with other adhesives. For example, use it in combination with PVA glue for a strong, flexible bond.

Creating custom textures

Explore creative ways to use rubber cement to create custom textures and effects.

Create texture on surfaces by applying rubber cement in patterns or designs. Once dry, paint over the cement to reveal unique textures.

In stenciling projects, use rubber cement as a resist. Apply the cement through stencils to produce intricate designs suitable for painting or coloring.

Conclusion

Rubber cement is a powerful and adaptable tool in crafting, offering flexibility, repositionability, and a non-permanent bond that makes it ideal for a variety of applications. By understanding its composition, applications, and advanced techniques, you can elevate your crafting projects to new heights. This comprehensive guide provides the knowledge needed to harness the full potential of rubber cement, ensuring that your creations are both durable and impressive.

FAQ:

What is rubber cement, and how does it work?

Rubber cement is a versatile adhesive made from rubber polymers dissolved in volatile solvents. The key components are rubber polymers, which can be natural or synthetic, and solvents like acetone or hexane that keep the rubber in a liquid form. When applied, the solvents evaporate, leaving behind a flexible, tacky rubber layer that adheres to surfaces. Its flexibility and repositionability make it ideal for crafting projects where adjustments are often needed.

What are the best applications for rubber cement in crafting?

Rubber cement is highly versatile and suitable for various crafting applications, including:

Paper Crafts: Ideal for scrapbooking, card making, and collage work due to its ability to bond paper without warping.

Photo Mounting: Useful for mounting photos in albums or displays with the flexibility to reposition.

Model Building: Excellent for assembling scale models and plastic kits, providing a strong yet flexible bond.

Textile Crafts: Can bond fabrics in certain applications, though it’s essential to test on a small sample first.

How should I apply rubber cement for the best results?

To achieve optimal results with rubber cement, follow these tips:

Apply Thin Layers: Use a brush or applicator to spread a thin, even layer of cement on one surface.

Allow to Dry: Let the cement dry until it becomes tacky to the touch before pressing the surfaces together.

Pressure Application: Apply consistent pressure using a rolling pin or similar tool to ensure a strong bond.

What are common issues with rubber cement, and how can I troubleshoot them?

Common issues with rubber cement include:

Drying too slowly: This may be due to high humidity or applying too much cement. Work in a well-ventilated area and use thin layers.

Difficulty Removing: Use a rubber cement pick-up or acetone to remove stubborn residues.

Weak Bond: Ensure the cement is tacky before bonding surfaces, and reapply if necessary.

What safety precautions should I take when using rubber cement?

To ensure safety while using rubber cement, follow these precautions:

Ventilation: Use rubber cement in a well-ventilated area to avoid inhaling fumes. Open windows or use a fan if necessary.

Protective Gear: Wear gloves and safety glasses to protect your skin and eyes from accidental contact.

Avoid Ingestion: Keep rubber cement away from children and pets and avoid ingestion, as it can be harmful if swallowed.