Robotics Powered by Artificial Intelligence are getting better and better every day. A lot of what robots can do now seemed like science fiction ten years ago. Previously unthinkable, robots can now learn, adapt, and collaborate with humans. The next generation of robots will be smarter, faster, and more useful in everyday life. The question is no longer if AI-powered robots will revolutionize business and society, but how soon and how far they will go

The Growth of Robotics and AI

Robots used to be very rigid about how they were programmed. They could put together pieces for cars or lift things, but they had problems when things changed without warning. AI and machine learning have made it possible for robots to “see,” “decide,” and “learn” in real time. Large language models (LLMs) and multimodal AI let robots see and work together better by letting them process text, voice, images, and sensor information all at once.

This jump allows machines to do more than just repeat things over and over. Robots using AI can now do surgery, gather crops, run warehouses, and even deliver items to your door. They don’t learn from scripts that are already written. They learn from systems that get smarter the more you use them.

New things are happening in AI robotics.

Let’s discuss some of the most essential ideas that will shape the future of AI-powered robots.

1. People and Machines Work Together Better with Robotics Powered by Artificial Intelligence

Robotics Powered by Artificial Intelligence can now move around more than just cages on factory floors. Cobots, or collaborative robots, can work safely with people. AI helps them interpret gestures, voice, and movements, making it easier for them to operate together. In hospitals, robots assist doctors with very precise tasks. They adapt in production to keep up with workers, which decreases stress and increases output

For instance, Nissan uses AI-powered cobots on its production lines to help people with tasks that need to be done again and again. This ensures the safety of the work and accelerates its pace.

2. Choosing things on your own

There are more things that can drive themselves than just cars. Amazon and ABB robots in warehouses utilize AI to find the best routes, handle logistics, and keep track of inventory with little help from people. This freedom lowers expenses and mistakes.

Farsound Aviation uses AI robots to help the supply chain work better. This speeds up distribution and lowers the risk of human error.

3. Using AI in more than one way

Robotics Powered by Artificial Intelligence can now get information from more than one place at once. A robot can see things with its eyes, follow directions with its voice, and move around using its sensors. These robots can operate in conditions that are continually changing and not always clear, since they can learn in numerous ways, just like people d

Zenni Optical uses AI-powered robots to make glasses that fit perfectly. They do this by integrating image recognition with automation.

4. Robotics Powered by Artificial Intelligence are Transforming Healthcare

Robots are changing healthcare in many ways, from doing surgery to taking care of the elderly. AI-powered surgical robots enable doctors to accomplish incredibly accurate work. Care robots assist in addressing the challenges faced by the elderly population by offering companionship, monitoring health issues, and administering medications.

In this case study, hospitals are utilizing Robotics Powered by Artificial Intelligence in the form of robotic nurses to transport supplies, clean rooms, and support staff. This allows human workers to focus on taking care of patients.

5. Long-lasting robots in farming

Farming can change a lot. AI-powered robots identify weeds, use water wisely, and pick crops with the least amount of waste. They look at the condition of the soil and guess how much food will be grown, which helps eco-friendly farming.

For instance, self-driving harvesters with AI and computer vision cut down on the need for chemicals, minimize labor costs, and increase output.

6. Adding to Daily Life

Robotics Powered by Artificial Intelligence are slowly becoming a part of daily life. Robot vacuums clean floors, delivery robots bring groceries, and litter robots pick up pet waste. These small innovations help people build trust in AI and robotics, making it easier for humans and machines to operate together seamlessly.

Real-life touch: Delivery robots increased quickly during the epidemic to make sure that service was safe and didn’t require interaction.

Coming Up:

Of course, any shift brings its own issues. Robots that use AI pose issues with safety for workers and technology.

Job Loss: As automation replaces some jobs, humans will need to acquire new skills and adapt to new regulations.

Ethical Limits: Is it okay for robots to make important judgments like health care or defense? There needs to be a worldwide agreement on borders.

Safety and Trust: AI errors or bias could cause accidents. It’s still important to test things and be honest about them.

We need to utilize smart regulations, training, and ethical design to fix these challenges.

New Ideas and Opportunities for Businesses with Robotics Powered by Artificial Intelligence

Despite current problems, there are significant opportunities for progress. Businesses can:

- Use cobots to make more things and hurt fewer people.

- Use AI robots to speed up shipping and make sure everything goes smoothly.

- Make farming and business more sustainable by using AI to analyze data.

- Make robots that people may utilize in smart homes to suit the growing need.

Inventors will have a wonderful time in the next ten years. You may offer whole new services using robotics, AI, the Internet of Things (IoT), and 5G. Think of robots as AI assistants that aid you in the real world and the digital realm.

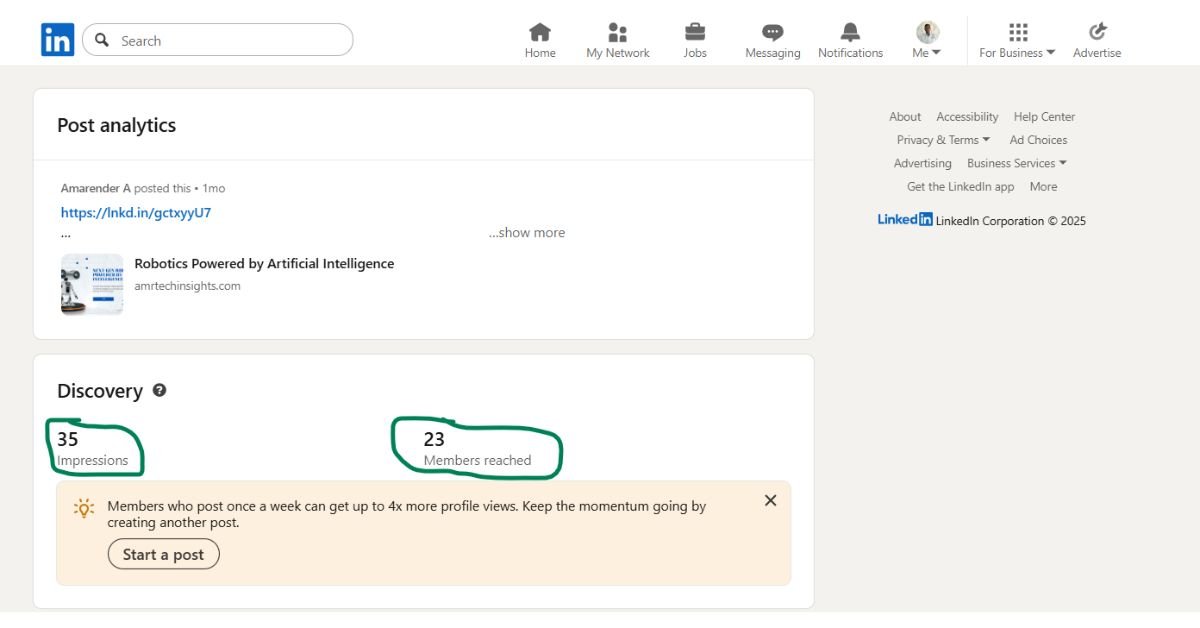

This LinkedIn post from my account, where I shared similar technical content on AI-powered robotics and emerging trends, received around 35 impressions and reached 23 members. The engagement demonstrates that the content resonated well with viewers, showing good visibility and interest within the professional community. It serves as evidence of positive reception and the value of sharing insights on such platforms. I invite you to read it as well to gain a better understanding of the topic and see how these ideas are being appreciated by an audience of professionals.

How to Prepare for the Next Wave

What can people, businesses, and professions do to prepare?

- Stay informed: Monitor the evolving landscape of AI and robots closely. Learning is the best way to stay safe and move ahead.

- Keep learning new things. It will be necessary to teach workers how to use AI, robots, and data.

- Try things out early: Businesses that utilize robots beforehand get more done and keep their clients.

- Be honest: Make robotic solutions that put safety, honesty, and fairness first.

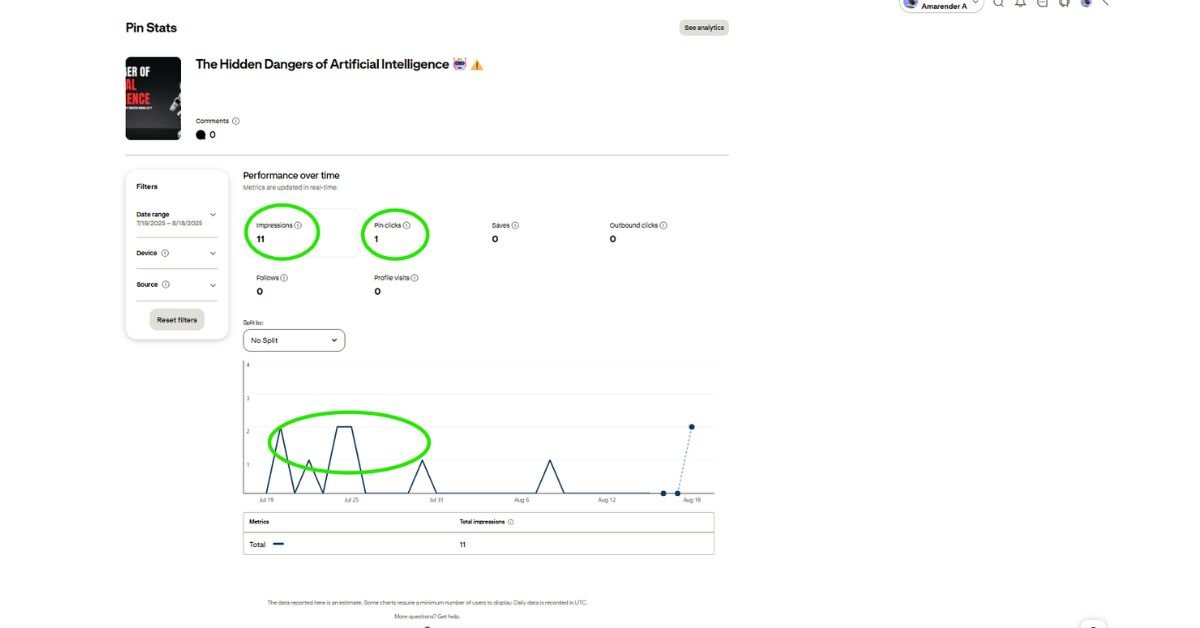

This image comes from my Pinterest account, where I shared similar content related to AI-powered robotics and emerging technology trends. The post received 11 impressions and 1 pin click, showing that even on smaller platforms, there is growing interest in these ideas. It highlights how technical insights can reach and engage viewers across different channels. I invite you to explore it as well for a broader perspective and to see how these concepts are being received by an online audience.

What to Look Forward to with Robotics Powered by Artificial Intelligence

The bond between AI and robotics will only get stronger in the future. Look for robots that:

- Learn from fewer examples and make changes more rapidly.

- Fit in perfectly with homes and businesses.

- Eliminate repetitive tasks to foster creativity among individuals.

- To deal with problems with sustainability, you need to get better at managing resources.

In the future, it’s not people against machines. It’s people and machines working together to solve issues that are too challenging for each to do alone.

The end: The road ahead

Robots that use AI are transforming what we can do. The future generation of robots will be able to change, work alone, and with other robots. They can work in hospitals, homes, factories, and on farms. They say they will be effective, long-lasting, and simple to use, but they also need to be carefully integrated into society.

I am an expert in AI, and I think that in ten years, robots will be more like friends than machines. They will affect not just businesses but also how people live, work, and come up with new ideas.

There are many chances. The duty is real. And the future is closer than we think.

Last updated on August 18, 2025

Hi, I’m Amarender Akupathni — founder of Amrtech Insights and a tech enthusiast passionate about AI and innovation. With 10+ years in science and R&D, I simplify complex technologies to help others stay ahead in the digital era.