Because of their unique qualities and uses, polymer concrete and conventional materials like normal concrete and cement-based composites stand out when selecting building materials. Polymer Concrete vs. Traditional Materials: The Pros You Need to Know-Making wise selections in building and remodeling projects depends on an awareness of the advantages and constraints of each. This paper explores in great detail the benefits of polymer concrete over conventional materials, therefore stressing why it might be a better choice for certain uses.

Knowing Polymer Concrete

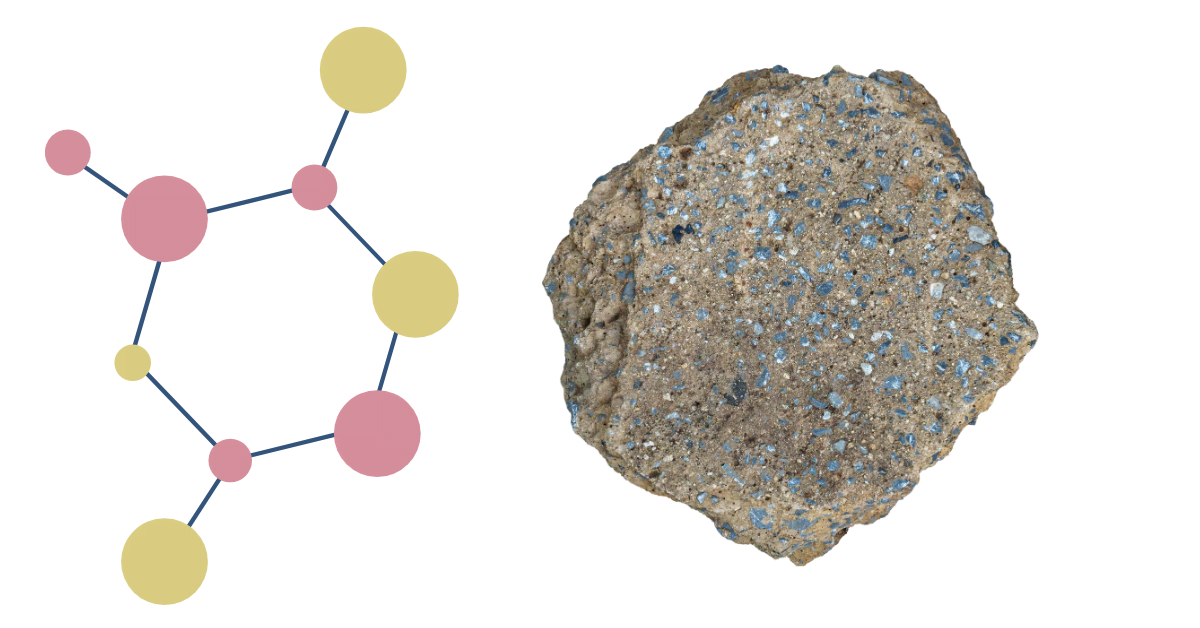

Combining conventional aggregate—such as sand and gravel—with a polymer binder rather than the typical cement makes polymer concrete a composite material. This creative material is interesting for specific uses because of several benefits it offers. The polymer binder, which is often an epoxy or polyester resin, offers unique qualities that distinguish polymer concrete from conventional alternatives.

Improved Strength and Resistance-Polymer Concrete vs. Traditional Materials: The Pros You Need to Know

Polymer concrete’s increased strength and durability above conventional concrete are among its most important advantages. Strong chemical bonds formed by the polymer binder between the particles provide a composite material that is quite wear- and tear-resistant. This makes polymer concrete more suitable for high-traffic environments like industrial flooring and bridge decks.

Superior Adhesive and Bonding Properties-Polymer Concrete vs. Traditional Materials: The Pros You Need to Know

Polymer concrete’s excellent compressive strength allows it to withstand pressure and heavy loads without degrading. While regular concrete may be easily degraded chemically, polymer concrete is far more resistant to acids, alkalis, and other corrosive agents. The polymer binder reduces shrinkage while curing, thereby reducing the risk of fractures and gaps. Excellent for repair and resurfacing operations, polymer concrete may create strong linkages with current concrete surfaces.

Relating to Conventional Materials

Financial Efficiency

Although polymer concrete’s initial cost is higher than that of conventional concrete, over time its advantages will exceed any expenses. Polymer concrete’s minimal maintenance and durability help to save a lot of money over time.

Longevity-Polymer Concrete vs. Traditional Materials: The Pros You Need to Know

Polymer concrete’s longer lifespan results in fewer replacements and repairs, reducing total expenditures. Usually less maintenance is required from polymer concrete, which helps to lower the need for frequent inspections and repairs.

Impact on the Environment

Regarding environmental effects, polymer concrete can be more green than conventional concrete in a few different respects. Polymer concrete’s generally reduced energy consumption results in a lower carbon footprint compared to conventional cement manufacturing. Some formulations of polymer concrete make use of recycled ingredients, therefore promoting sustainability and resource efficiency.

Uses for Polymers in Concrete-Polymer Concrete vs. Traditional Materials: The Pros You Need to Know

Polymer concrete’s specific qualities make it suitable for a variety of specialized uses:

Flooring in Industry

Because of its resistance to chemicals and abrasion, as well as its strength, polymer concrete is perfect for industrial flooring. It is extensively used in manufacturing facilities, warehouses, and labs where heavy machinery and strong chemicals are present.

Bridge Decks and Paved Roads

Polymer concrete provides a strong surface that can withstand heavy loads and severe weather on bridge decks and busy pavements. Its dependability for infrastructure projects stems from its resistance to de-icing salts and chemicals.

Maintenance and Repair: Rehabilitation

Polymer concrete provides a viable answer for repairing and rehabbing already-existing concrete buildings. Its excellent adhesive properties allow it to adhere effectively to ancient concrete surfaces, giving it a smooth and long-lasting appearance.

Difficulties and Thoughts to Remember

Despite its advantages, polymer concrete presents a number of challenges that need consideration.

Greater Initial Outlay

Polymer binders are more expensive than ordinary concrete, so polymer concrete may initially cost more. Still, the long-term benefits and reduced maintenance costs assist to balance the investment’s cost.

Professional Installation

Using polymer concrete calls for certain knowledge and tools. Proper execution of the application is crucial for achieving the intended results and performance.

Sensitivity to Temperature

During curing, polymer concrete can be sensitive to temperature changes. Properly managing the temperature during the curing process will help you avoid any problems.

Polymer Concrete’s Practical Uses and Case Studies

Several practical uses have demonstrated the distinct qualities of polymer concrete, highlighting its advantages over conventional materials. These case studies will help you better understand the applications and factors that make polymer concrete successful.

1. Commercial Carpeting

Industrial flooring is one of polymer concrete’s most well-known uses. Facilities with tough circumstances, such as industrial facilities, warehouses, and labs, need flooring solutions that are resilient and long-lasting. As an illustration:

Case Study: Plant that Produces Automobiles For its production floor, an automobile manufacturing facility used polymer concrete. There is a lot of heavy equipment movement in the region, and oil and chemical spills happen frequently. The perfect option was polymer concrete because of its resilience to abrasion and chemical assault. The material’s longevity and ease of cleaning resulted in a significant reduction in maintenance expenses and downtime for the facility.

Pharmaceutical Laboratory Case Study The pharmaceutical laboratory selected polymer concrete for its use due to its resistance to abrasive cleaning solutions and its capacity to inhibit bacterial development. The flooring system’s chemical resistance and smooth finish enhanced the area’s sterility and ensured strict adherence to hygiene regulations.

2. Infrastructure and Bridge Decks

Because of its durability and strength, polymer concrete is a viable option for important infrastructure projects. Its resistance to severe weather and de-icing salts is very significant.

Rehabilitation of Urban Bridges: A Case Study A large-scale urban bridge restoration project used polymer concrete to strengthen and restore the deck. The polymer concrete’s quick cure time and excellent adhesion to the preexisting surfaces reduced traffic disturbance. Compared to previous procedures, we greatly increased the bridge’s lifespan and completed the repair work more quickly.

Coastal Highway Pavement Case Study The exposure of coastal roadways to saltwater and extreme weather causes typical concrete pavements to deteriorate more quickly. As part of a test project, we resurfaced a coastal roadway using polymer concrete. Because of the material’s resilience to moisture and salt, the surface lasted longer between maintenance and repairs.

3. Current Concrete Upkeep and Restoration

Because of its strong adhesive qualities, polymer concrete is excellent for resurfacing and restoring older concrete buildings. The following applications help to prolong the life of deteriorating infrastructure:

Case Study: Resurfacing the Airport Runway An airport runway with surface fractures and deterioration underwent restoration using polymer concrete. The new surface increased durability and friction, improving safety and lowering the frequency of resurfacing. The polymer concrete formed a smooth and long-lasting new layer on the original runway because it stuck to it nicely.

Case Study: Restoring Historic Structures The restoration of a historic structure involved the use of polymer concrete to restore degraded concrete components. Because of the material’s excellent bonding with the original surfaces, precise restoration work was possible, preserving the building’s structural integrity and aesthetic value.

4. Uses in Homes and Businesses

Polymer concrete is advancing in residential and commercial contexts, in addition to its use in industry and infrastructure.

Case Study: Flooring for Expensive Retail Stores A high-end retail establishment chose polymer concrete for its contemporary design and resilience. The material provided a sturdy solution for areas with heavy foot traffic while also allowing for creative design possibilities such as unique hues and patterns.

The case study showcases an opulent driveway for a home. A luxury residence utilized polymer concrete to create a chic and long-lasting driveway. Homeowners seeking both functionality and beauty frequently choose this material because of its stain resistance and ability to hold up over time.

In Essence

For many uses, polymer concrete offers a range of advantages that make it an appealing alternative. Compared to conventional materials, its improved durability, excellent bonding, and chemical resistance provide many benefits. The long-term advantages usually outweigh any initial cost and particular installation needs, even if these may be factors to take into account. For uses calling for extraordinary performance and lifetime, polymer concrete is a superior option than traditional concrete and cement-based products.

FAQ:

Describes polymer concrete?

Made from standard aggregates like sand and gravel combined with a polymer binder, such as epoxy or polyester resin, polymer concrete is a composite material unlike the usual cement. This special mix produces a material with improved characteristics like more strength, durability, and chemical resistance.

How different is polymer concrete from traditional concrete?

Polymer concrete stands apart from ordinary concrete mostly in its binder. Conventional concrete uses cement as a binder; polymer concrete uses polymer resins, which provide improved adhesive characteristics, reduced shrinkage, and increased chemical and abrasion resistance. These variations make polymer concrete more appropriate for demanding situations like heavy traffic.

Why should one use polymer concrete mostly?

The key benefits of polymer concrete are better strength and durability, great chemical resistance, outstanding adhesive qualities, and low maintenance needs. Perfect for industrial flooring, bridge decks, and maintenance work, it is quite resistant to acids, alkalis, and de-icing salts.

Fourth FAQ: For what usually purposes is polymer concrete used?

Commonly utilized in industrial flooring, polymer concrete’s chemical and abrasion resistance makes it Its strength and longevity under large loads and strong storms help it also be utilized in paved roads and bridge decks. Furthermore, because of its great bonding capacity, polymer concrete is efficient for maintenance and repairs of current concrete buildings.

The fifth FAQ is if employing polymer concrete presents any difficulties?

Indeed, certain difficulties include the requirement of expert installation to guarantee correct application and performance and the greater initial cost compared to traditional concrete. Furthermore, sensitive to temperature variations during curing, polymer concrete calls for cautious control to prevent any problems.