Building is undergoing a revolution in an era where environmental concerns are driving innovation across all industries. We are reexamining traditional construction procedures and developing new approaches to fulfill the technical requirements and sustainability goals of contemporary structures. Particle-Based Eco-Engineering-One breakthrough is particle-based eco-engineering, which uses nanotechnology, materials science, and environmental engineering to generate sustainable, high-performance building materials. This blog post describes particle-based eco-engineering, its scientific basis, practical applications, problems, and future possibilities.

Understanding Particle-Based Eco-Engineering

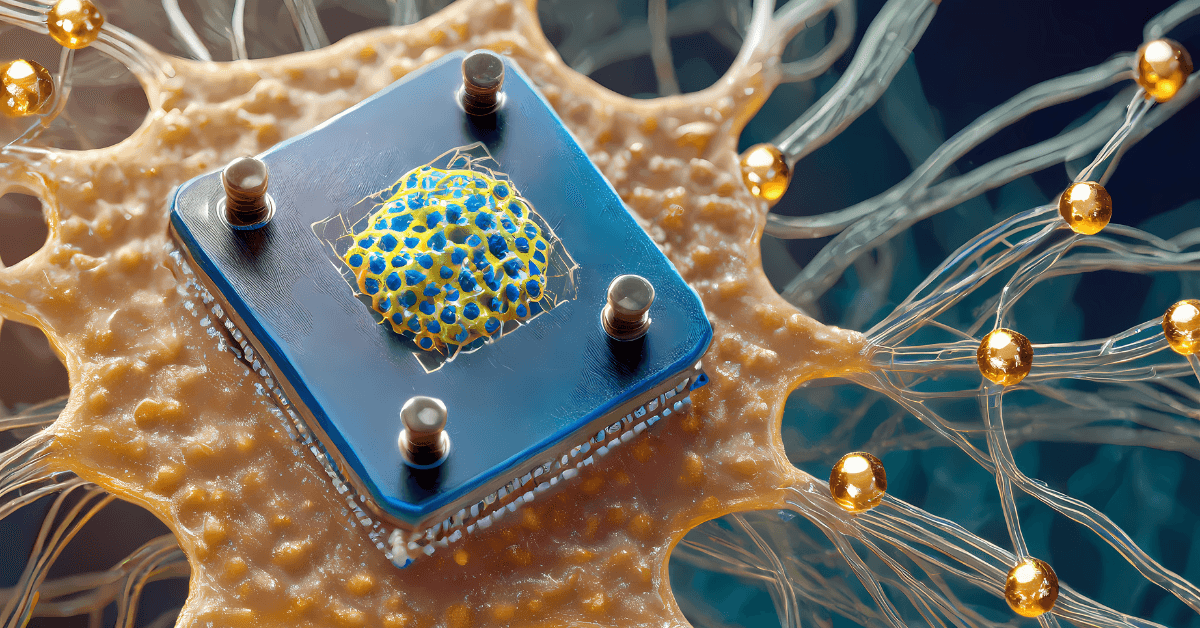

Particle-based eco-engineering improves building materials’ performance, durability, and sustainability by adding nanometer- to micrometer-sized designed particles. These natural, synthetic, or designed composite particles change the physical, chemical, and mechanical characteristics of concrete, mortar, and composites.

Strength and durability of traditional building materials depend on macro- and micro-scale properties. Engineers can control porosity, permeability, and thermal insulation by manipulating particles. This creates buildings that function better under stress and have a lesser environmental effect over time.

The Particle Science-Particle-Based Eco-Engineering

The study of nanoparticles and microparticles powers particle-based eco-engineering. The introduction of these highly tailored particles into a material matrix has allowed researchers to:

Concrete formulas greatly improve mechanical strength and durability by including cutting-edge nanoparticles like graphene, carbon nanotubes (CNTs), and nano-silica. By filling up micro-scale gaps in the concrete matrix, these designed particles increase the density and homogeneity of the material. This process significantly increases the compressive and tensile strength of the material. Researchers have found that adding more nano-silica to concrete makes its flexural, split tensile, and compressive strengths better. This is because it improves the structure of the pores and encourages water to enter the concrete.

Additionally, the addition of these nanoparticles lowers permeability, increasing the material’s resistance to environmental influences. This benefit holds particular significance in regions subjected to chemicals, pollution, or harsh weather. It has also been shown that adding graphene and carbon nanotubes to building materials increases their strength and lowers their vulnerability to fractures and structural damage.

In addition, tailored particles may improve acoustic and thermal insulation qualities, which will stabilize interior temperatures and increase energy efficiency. It’s also important to notice new developments in self-healing materials; microscale encapsulated healing agents may self-heal fractures and increase the longevity of buildings. For instance, it has been investigated to enhance asphalt mixtures’ self-healing qualities by using nano-silica.

The role of nanotechnology and materials science

Nanotechnology is essential to particle-based eco-engineering because it allows tiny material manipulation. Materials research has advanced fast, revealing how nanoscale interventions might improve macroscopic systems. As an example:

Researchers have shown that adding nano-silica to concrete enhances its microstructure by filling cement particle gaps. Densification boosts strength and decreases water intrusion.

Construction materials are incorporating carbon nanotubes (CNTs), known for their high tensile strength and electrical conductivity, to create smart composites. These composites have integrated sensors that provide real-time structural integrity data.

Graphene: This single layer of carbon atoms is a wonder material for its strength and thermal qualities. Its use in building materials will improve durability and energy efficiency.

Engineers may build eco-friendly materials that lessen construction projects’ environmental impact and outperform their conventional equivalents using these nanoparticles.

Sustainable Construction Applications-Particle-Based Eco-Engineering

Several sustainable building solutions use particle-based eco-engineering:

Enhancing Concrete and Mortar

Although concrete is the most widely used construction material in the world, the environmental effect of producing cement, the substance’s main binder, is substantial. To counteract this, chemical engineers are adding nanoparticles to concrete, which offers many advantages:

Decreased Cement Consumption: By improving the mechanical qualities of concrete, the use of nanoparticles enables a decrease in the amount of cement needed. Since the manufacture of cement is a significant source of CO₂ emissions during manufacturing, this drop immediately translates into fewer emissions throughout this process.

Increased Durability: By reducing permeability, nanoparticles enhance particle packing within the concrete matrix. By increasing the material’s resilience to freeze-thaw cycles, this densification prolongs the life of buildings.

Self-Healing Structures: Concrete may self-heal fractures as soon as they appear thanks to the use of microencapsulated healing chemicals. This self-healing capacity lowers maintenance costs and greatly extends the structural lifespan.

Top-performing coatings and sealants

Particle-based eco-engineering is changing building coatings and sealants as well as structural materials. Advanced materials provide:

Photocatalytic nanoparticles like titanium dioxide degrade organic contaminants on building surfaces.

Weather Resistance: Nano-additives make sealants more UV, water, and chemical-resistant.

Enhanced Thermal Regulation: Specialized coatings reflect solar radiation, decreasing building heat absorption and cooling energy costs.

Materials that adapt

Creating smart materials that interact dynamically with their surroundings is intriguing. External factors may change these materials:

Particles that change phase or shape with temperature may increase energy efficiency.

Self-Sensing Composites: Conductive nanoparticles detect stress, strain, and damage, allowing predictive maintenance and decreasing unexpected failures.

Environmental Benefits and Sustainability-Particle-Based Eco-Engineering

Particle-based eco-engineering improves material performance and reduces construction’s environmental effect. Important environmental advantages include:

Reduced Resource Use

Engineers may design structures with less raw material by improving material performance. Stronger concrete uses less material to maintain structural integrity, saving resources.

Energy efficiency and lower emissions

Buildings use less energy with better insulation. These materials cut energy costs and greenhouse gas emissions by keeping the interior cool in the summer and warm in the winter. These materials’ resilience and self-healing characteristics extend building lifespans, saving money on repairs and replacements.

Recycling and Circular EconomyEngineered particles in construction materials enable recycling and reuse at the end of a building’s existence. Many nanoparticles come from plentiful, natural sources. Their usage in high-performance composites may simplify component separation and recycling, promoting a circular building economy.

Technical Benefits: Theory to Practice

Particle-based eco-engineering has technological benefits beyond environmental ones. Several materials science variables favor this approach:

Better microstructure

Nanoparticles provide a more homogenous microstructure, minimizing failure sites. Filling micro-voids creates a thick, linked material matrix.

Improved Mechanical Properties

Numerous studies have indicated that nanoparticles may greatly increase the compressive and tensile strengths of construction materials. Furthermore, because material failure might have disastrous results, this enhancement is especially helpful when building high-rise buildings and important infrastructure projects. Furthermore, adding nanoparticles to building materials improves their resilience and further guarantees the security and lifespan of these constructions. Utilizing such state-of-the-art materials could also lead to more affordable designs that improve performance overall. To sum up, the use of nanoparticles in building is a promising development that will eventually lead to safer and more durable infrastructure.

Multiple Functions

Multi-functional materials are one of particle-based eco-engineering’s most unique features. One composite can incorporate support, thermal insulation, and self-sensing capabilities. This multi-functionality minimizes material complexity and boosts construction performance.

Health of Economy

While incorporating sophisticated particles may initially be more expensive, the long-term savings in maintenance, energy consumption, and environmental effects make particle-based eco-engineering economically feasible. As research and manufacturing scale up, prices should fall, making these solutions more affordable for additional applications.

Issues and considerations

Particle-based eco-engineering faces problems despite its potential. Addressing the following concerns is crucial.

Cost/Scalability

Nanoparticle synthesis and incorporation into building materials are costly. The industry must create cost-effective, high-quality, large-scale manufacturing processes for wider use.

Health and Safety Concerns

Nanoparticles raise health and environmental concerns. When incorporated in a stable matrix, many nanoparticles are inert and harmless, but their manufacturing, handling, and disposal are under study. Regulatory requirements must keep up with technology to assure safety.

Technology Complexity

Nanoscale material engineering demands sophisticated lab equipment and expertise. Bringing research labs and on-site construction together is difficult. Effective collaboration between researchers, engineers, and construction experts is necessary to maximize particle-based eco-engineering advantages.

Regulation and Standardization

The absence of standardized guidelines can hinder the widespread adoption of emerging technologies. Therefore, establishing universal nanoparticle standards for building materials is crucial to ensure quality, safety, and interoperability across various projects and international borders.

Future plans and innovationsFuture prospects are bright for particle-based eco-engineering. These innovations may further change the building industry:

Integration with digital technologies

Material science and digital technologies will shape eco-engineering. Smart, self-monitoring materials that interface with IoT devices are coming. These materials might give real-time structural health, environmental, and energy efficiency data for predictive maintenance and better building management.

Self-Healing Material Advances

Self-healing composite research is increasing. Future materials might autonomously mend fractures and damage utilizing microencapsulated healing agents or reactive nanoparticles, greatly prolonging structural life and minimizing maintenance costs.

Techniques for Sustainable Production

Demand for nanoparticles and modified particles will drive the search for sustainable manufacturing solutions. Green chemistry and recycling innovations will help make these materials as eco-friendly as their products.

Cross-disciplinary cooperation

Materials scientists, structural engineers, environmentalists, and policymakers must work together to execute particle-based eco-engineering. Together, these organizations can solve technological, economic, and regulatory issues, ushering in a new age of sustainable building.

Conclusion

Particle-based eco-engineering is shaping the building sector now, not only in the future. Engineers may use nanoparticles and sophisticated materials science to build stronger, more lasting, and more sustainable buildings. This technology has several advantages, from decreasing carbon footprints and energy usage to self-healing and sophisticated monitoring.

Particle-based eco-engineering may help the building sector balance environmental sustainability and performance. It combines cutting-edge research and practical engineering to provide creative, required answers in today’s fast-changing environment.

Architects, engineers, and industry experts must adopt these new materials and methods to remain ahead. The promise of increased longevity, fewer maintenance costs, and lower environmental impact may change how we construct.