How Do Paints Use Nanotechnology? Changing Coatings for a More Intelligent Future

Because nanotechnology improves performance, durability, and sustainability, it is revolutionizing the paint business. How is Nanotechnology Used in Paints-Nano-engineered paints use cutting-edge science to tackle long-standing issues, such as corrosion-resistant metals and self-cleaning walls. Let’s examine how minute particles in contemporary coatings have significant effects.

What does paint nanotechnology mean?-How is Nanotechnology Used in Paints

The manipulation of materials at the atomic or molecular scale (1–100 nanometers) is known as nanotechnology. Manufacturers include nanoparticles such as zinc oxide, titanium dioxide, or silica in paints. These particles change the characteristics of the paint, providing advantages that conventional formulae cannot match.

For example, nanoparticles provide smoother surfaces by filling up minute gaps. Additionally, they improve adhesion, making paint adhere to surfaces more effectively. Their tiny size allows for precise control over color, texture, and functionality.

1. Advantages of nano-enhanced paints is their increased durability and scratch resistance.

Paint layers include thick, interconnecting networks of nanoparticles. This structure is resistant to chemical, UV, and abrasion damage. For instance, cars with nanocoatings keep their sheen longer even in inclement weather.

2. Surfaces That Clean Themselves

Water and grime are repelled by hydrophobic nanoparticles, such as silica. Raindrops roll off a surface coated with nanoparticles, bringing dirt with them. This method lessens the need to clean solar panels or structures.

3. Protection Against Corrosion

Nanoparticles of zinc or cerium oxide serve as sacrificial barriers. They delay the production of rust by oxidizing before the underlying metal does. These coatings are increasingly used to increase the structural longevity of ships and bridges.

4. Better Insulation Against Heat

Hollow ceramic microspheres are present in certain nanopaints. Because they reflect heat, interior temperatures are kept warmer in the winter and cooler in the summer. These coatings can reduce energy expenses in homes by as much as 20%.

5. Properties of Antimicrobials

By breaking down bacterial cell membranes, silver nanoparticles stop the growth of mold and mildew. Antimicrobial paints are being used more often in hospitals to keep spaces clean and lower illness rates.

How Do Paint Formulations Use Nanoparticles?-How is Nanotechnology Used in Paints

There are three main ways that nanoparticles alter the behavior of paint:

Surface Interaction

They form strong bonds with pigments and resins because of their high surface-area-to-volume ratio. This results in the production of consistent coatings that do not peel or break.

Properties That React

Certain nanoparticles, such as titanium dioxide, degrade contaminants when exposed to ultraviolet light. This “photocatalytic” action lowers air pollution and maintains cleaner building exteriors.

Strengthening of Structures

Carbon nanotubes or graphene additions strengthen paint films. Coatings are perfect for high-impact locations like industrial floors since these materials absorb tension.

Applications of Nano-Paints in the Real World:

1. Automotive Sector

Nano-clear coatings protect car finishes from UV fading and scratches. When heated, self-healing versions even fix little swirl blemishes.

2. Construction and architecture.

Thermally reflecting nanopaint reduces HVAC loads in buildings. After using these coatings, the famous Patni Tower in Mumbai reduced its energy use by 15%.

3. Aerospace and Marine

Anti-fouling nanopaints on ships stop barnacles from growing, increasing fuel economy. Lightweight nano-coatings are also used in airplanes to lower drag.

4. Medical Facilities

Antimicrobial nanopaints on equipment and walls stop the spread of pathogens. According to 2022 research, they lower hospital-acquired illnesses by 30%.

5. Green Energy

By reducing dust accumulation, solar panels covered with self-cleaning nano-paints produce 5–10% more electricity.

Limitations and Difficulties with Nano-Paints-How is Nanotechnology Used in Paints

Despite its potential, nanotechnology in paints confronts challenges:

High Costs of Production

Nanoparticle synthesis requires sophisticated equipment, which drives up costs. Nano-paint can cost up to three times as much per liter as traditional alternatives.

Safety and health issues.

During application, breathing in nanoparticles might be dangerous. Until the long-term consequences are known, researchers recommend rigorous PPE usage and ventilation.

Regulatory Omissions

Clear regulations for the safety of nanomaterials are lacking in many nations. Inconsistent rules impede consumer trust and industry acceptance.

Effects on the Environment

Silver is one of the nanoparticles that might damage aquatic life if it washes into streams. Researchers are currently developing bio-based nanosilica as an environmentally friendly substitute.

Prospective Developments in Nano-Paint Technology-How is Nanotechnology Used in Paints

1. Intelligent Paints

Researchers are developing paints that change color in response to electricity or temperature. Imagine using a smartphone app to change the color of walls!

2. Coatings that purify the air

Titanium dioxide nanoparticles may break down VOCs and NOx gases. The air quality around covered structures has already improved in pilot programs in dirty cities.

3. Nano-paints that decompose naturally

Plant-based nanoparticles are developed by startups such as GreenNano Tech. By safely decomposing, these coatings mitigate the microplastic pollution caused by conventional paints.

4. Paints That Produce Energy

Paints using quantum dots might capture solar energy. They could transform any surface into a power source, despite being experimental.

How to Pick Your Project’s Best Nano-Paint

Before making a purchase, take into account the following factors:

Goal: Give top priority to attributes like antibacterial qualities for hospitals or UV resistance for exteriors.

Make sure the paint is compatible with your substrate (concrete, wood, or metal).

Certifications: For safety, look for eco-labels such as EPA certification or Green Seal.

Budget: Strike a balance between initial expenditures and long-term savings via energy efficiency or durability.

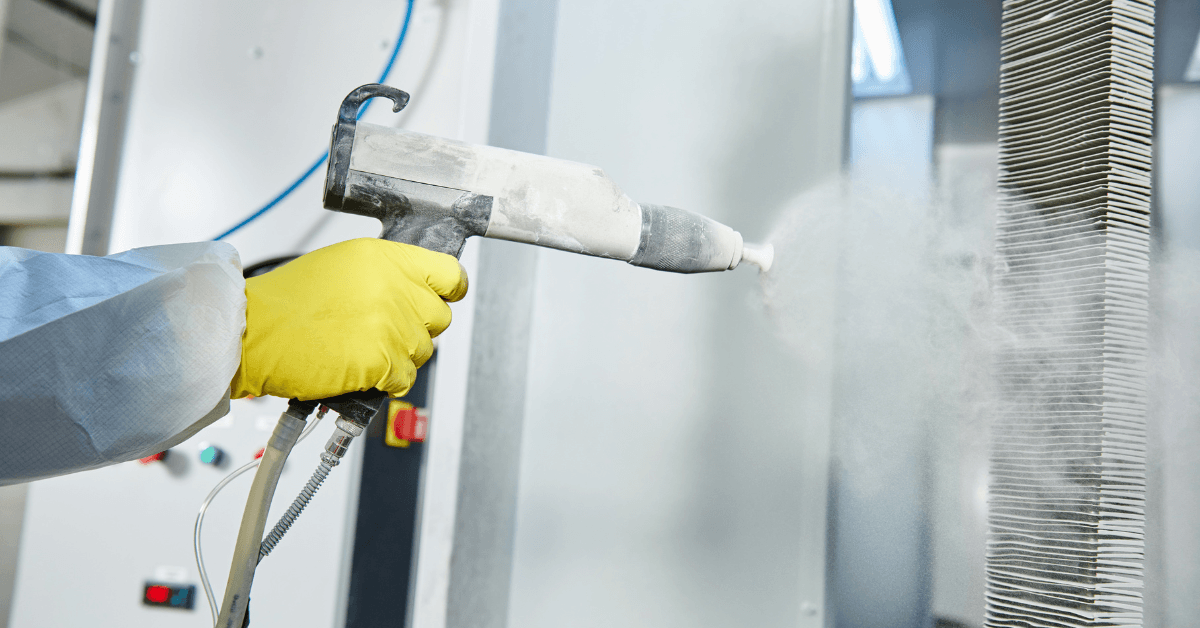

Using Nano-Paints: Optimal Techniques

Surface Preparation: To increase adhesion, carefully clean and sand surfaces.

Priming: If advised, use a nano-primer; it improves performance.

Mixing: To prevent breaking down nanoparticles, carefully stir the paint.

Application: Use brushes, rollers, or sprayers to apply thin, uniform coatings.

Curing: Give it enough time to dry completely, usually 24 to 48 hours, before exposing it.

Conclusion: Accepting the Nano-Paint Revolution

Paints containing nanotechnology are not science fiction; they are here to solve practical issues and advance sustainability objectives. Nano-coatings expand the capabilities of paints, enabling self-cleaning houses and infection-resistant hospitals. These smart paints will soon be widely available as research advances and costs decrease. Are you prepared to improve your upcoming project? Experience the coatings of the future by immersing yourself in the nano-paint revolution now!

FAQ:

How is nanotechnology used in paint?

- Nanotechnology improves paints by using nanoparticles like titanium dioxide or silica. These particles increase durability, resist water, and produce surfaces that clean themselves. They also successfully lower maintenance requirements and increase UV resistance.

How is nanotechnology used in adhesives?

- Nanotechnology uses silica or carbon nanotubes to strengthen adhesives. These chemicals withstand heat, improve flexibility, and speed up curing. Additionally, they make it possible for electronics to create conductive connections, which enhances performance in the automobile and aerospace sectors.

What companies are using nanotechnology in paint?

- Leading manufacturers of nano-enhanced paints, such as self-cleaning coatings, are AkzoNobel, PPG Industries, and Sherwin-Williams. Additionally, innovative startups like NanoPhos provide environmentally friendly solutions for energy-efficient buildings and industrial uses throughout the world.