Overview

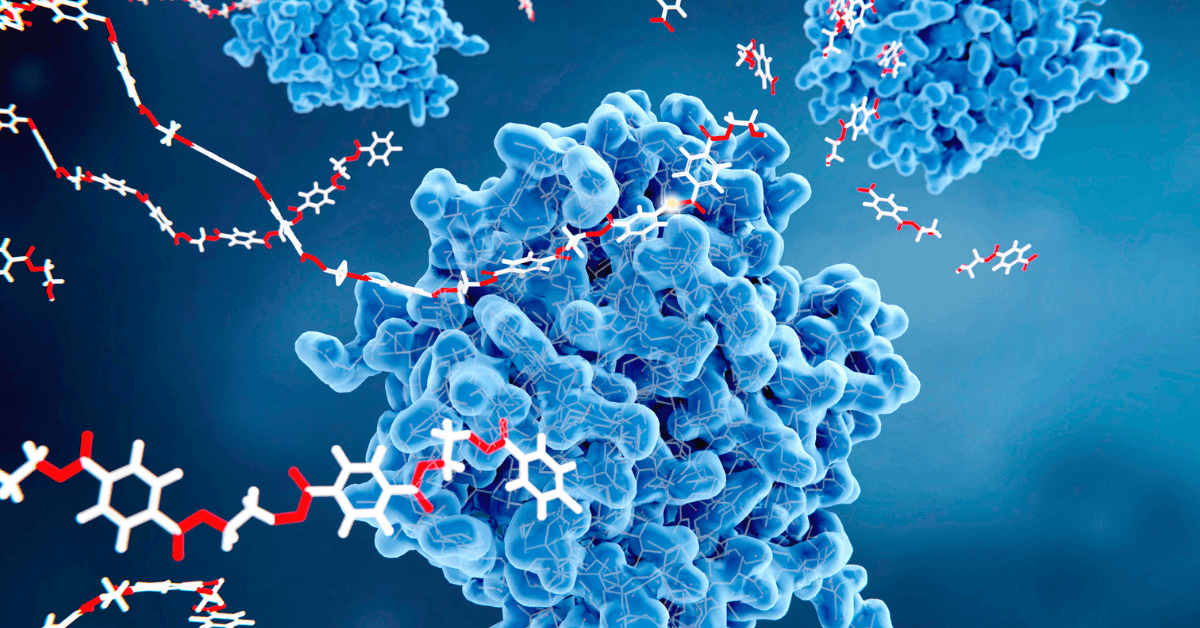

A promising new area of biotechnology, enzyme-polymer conjugates are constantly in the works. Enzyme-Polymer Conjugates-By mixing enzymes (biological catalysts) with synthetic polymers, these conjugates become more stable, dissolve more easily, and work better as catalysts. Many sectors have found uses for this combination of biochemistry and materials science, including bioengineering, diagnostics, and medication delivery.

Here in the blog, we’ll examine the structure, functions, applications, and advantages of enzyme-polymer conjugates from a scientific perspective. Furthermore, we will go over the present state of enzyme-polymer conjugate technology, its potential in the market, and any upcoming developments in this cutting-edge biotech field.

How Are Enzyme-Polymer Conjugates Defined?

Attaching enzymes to polymers, either synthetic or natural, creates biohybrids known as enzyme-polymer conjugates. Enzymes, in their original forms, lack certain characteristics that the conjugation process can acquire. One example of an improved property is:

Enzymes are notoriously sensitive to changes in temperature and pH, making them more unstable in hostile environments. Polymers encase them, maintaining their catalytic activity for extended durations.

Improved Solubility: We can aid enzymes that are either insoluble or only partially soluble in water. Enzymes have increasing utility in bioprocessing and pharmaceuticals due to their solubility when coupled with polymers.

Release Control: We can engineer EPC to release the enzyme in a regulated and sustained manner, making them ideal for medication delivery systems.

Enzyme-Polymer Conjugate Structures

We can categorize enzyme-polymer conjugates based on the polymer type and the conjugation method. Most notably, they are the varieties below:

Covalent bonds link the enzyme and polymer in these conjugates, ensuring strong attachment and stability. Most commonly, the carbodiimide coupling, thiolene reaction, and click chemistry processes accomplish covalent bonding.

Low-energy interactions like electrostatics, hydrophobicity, or van der Waals forces characterize non-covalent conjugates. This type of conjugate is less stable than covalent conjugates, but it is easier to form and can be reversed.

A type of enzyme conjugation known as “polymerized enzyme conjugate” encases the enzyme in a polymer network. This arrangement allows for the formation of enzyme aggregates with improved stability and mechanical characteristics.

Why Enzyme-Polymer Conjugates Work in Science

An understanding of these fundamental concepts is necessary for the synthesis of EPC:

1. Choosing the Right Polymer

In order to control the conjugate’s characteristics, the polymer choice is paramount. Commonly, enzyme conjugates utilize the following polymers:

Biocompatible and hydrophilic, polyethylene glycol (PEG) is a polymer that finds extensive use in many applications. Enzymes can increase their solubility and reduce immune responses in therapeutic applications by attaching PEG to them, a process known as PEGylation.

As a biodegradable polymer, polylactic acid (PLA) has several potential uses in medicine delivery and tissue engineering. Controlled release features can be achieved when enzymes are conjugated with PLA.

Natural polysaccharides (like dextran) are very biocompatible and find widespread usage in medicine.

2. Conjugation

There are a number of techniques used to bond enzymes to polymers, such as:

One approach is covalent binding, which uses chemical reagents to form stable bonds between the enzyme and the polymer. Common crosslinkers consist of epoxides, glutaraldehyde, and carbodiimide.

To make the enzyme more manageable, one option is to physically encase it in a polymer matrix; however, this method may compromise the enzyme’s catalytic performance.

Because it is very specific and has a low rate of side reactions, click chemistry has become a useful way to make enzyme-polymer conjugates.

3. Health and exercise

The enzyme’s stability and activity after conjugation are determined by the structure of the conjugate. In addition to shielding the enzyme from damage, the polymer can also obstruct its active site, making it less effective in catalyzing reactions. Maintaining a steady state while maximizing enzyme activity requires an optimal polymer-to-enzyme ratio.

Polymer-Enzyme Complexes and Their Potential Use

Conjugates of enzymes and polymers are revolutionizing numerous industries. A few of the most intriguing uses for them are as follows:

1. Medication Distribution Networks

When it comes to regulated medication delivery, enzyme-polymer conjugates are crucial. It is possible to deliver medicines precisely and continuously by linking enzymes to polymers that respond to changes in pH or temperature.

Polymer-conjugated enzymes could help target the release of therapeutic enzymes to disease sites, which could lower the risk of side effects. This approach works well for enzyme replacement treatments, which aim to provide people with enzyme deficits with functional enzymes.

2. Biocatalysis in Manufacturing

Industrial biocatalysis is another area that finds usage for enzyme-polymer conjugates. The catalytic function of enzymes is essential in many industrial processes. Because of their instability and high cost, enzymes have limited long-term applications. Conjugating enzymes with polymers allows industries to enhance enzyme stability, leading to cost savings and reusability.

One example of using enzyme-polymer conjugates is:

Biosensors: They contribute to the enhanced sensitivity of chemical detection.

One area where enzyme-polymer conjugates have shown promise is in the food and drink industry, namely in the fermentation of alcoholic and non-alcoholic beverages.

For the purpose of environmental remediation, these conjugates can be employed in waste treatment to break down contaminants in polluted water or soil more effectively.

3. Enhanced Biosensor Performance

Diagnostics and Biosensors Enzyme-polymer conjugates are gradually finding their way into diagnostic and biosensor devices. When enzymes are used as diagnostic sensors, they interact with target molecules to make signals that can be picked up. Polymer conjugation makes enzymes more stable, which in turn makes biosensors more sensitive and accurate.

One use for enzyme-polymer conjugates is to make electrochemical sensors that can find biomolecules, infections, or pollutants in the environment.

4. Stem Cells and Regenerative Medicine

Enzyme-polymer conjugates control the breakdown of scaffold materials in tissue engineering and regenerative medicine. Polymers can control the release of these enzymes at specific intervals to aid in tissue growth and repair. Because the conjugates encourage cell attachment and differentiation, they are useful for generating synthetic tissues.

Maximizing Enzyme-Polymer Conjugate Productivity

Biotechnological and medicinal uses of enzyme-polymer conjugates are among the most numerous and extensive.

The following are among the most significant benefits:

1. Improved enzyme stability first.

No matter how severe the environment, including the temperature, salinity, or pH levels, enzyme-polymer conjugates remain more stable than unbound enzymes. For enzymes to be useful in industrial settings, where they must remain active for extended periods of time, this stability is paramount.

2. Optimized Bioavailability and Insoluble Phase

Enzymes find increased utility in medicine and industry when encased in polymers, which increase their solubility in water. Enhanced solubility plays a crucial role in enzyme treatments and drug delivery systems.

3. Decreased immunogenicity

In enzyme-polymer conjugates, the immune system is less likely to recognize the therapeutic enzymes. This is especially true when biocompatible polymers like PEG are used to deliver drugs. This prevents the body from producing an immunological reaction.

4. Focused Distribution

In targeted medication delivery, enzyme-polymer conjugates make it possible to deliver therapeutic enzymes to exact locations. This improves treatment effectiveness while reducing side effects. This ensures that the enzymes only work on the intended tissues or environments.

Problems and potential solutions with enzyme-polymer complexes

Problems do arise with enzyme-polymer conjugates, despite their great promise:

Production Expenses: Premium polymers, such as PEG, can drive up the price of enzyme-polymer conjugate synthesis. This may restrict their broad use in business.

Loss of Enzyme Activity: Some conjugation methods result in enzymes with lower enzymatic activity, which makes them less useful in certain contexts.

Future developments in materials science, conjugation methods, and cost-cutting initiatives should make these obstacles obsolete. The goal of research into enzyme-polymer conjugates is to enhance their activity, stability, and cost-effectiveness, indicating a promising future for these compounds.

Finally- Where They’re Heading

Enzyme-polymer conjugates are making a significant impact in various fields, including environmental biotechnology and pharmaceuticals. They make targeted administration easier and improve the stability, solubility, and activity of enzymes, which makes them essential in many areas. We anticipate the emergence of many more inventive applications, ranging from advanced biocatalysis to customized medicine, as research and development progress.

Get ready to explore the fascinating realm of enzyme-polymer conjugates! Our newsletter and blog provide you with up-to-date information about biotechnology developments, so you can stay informed about the newest research, applications, and discoveries. We can make a difference in the world by working together to realize the full promise of enzyme-polymer conjugates for future generations.