The Impact of Automated Inspection on Quality Control in Different Sectors

Automation is transforming various industries globally in today’s fast-paced, technology-driven society. Automated Inspection-Automated inspection stands out among the many areas that have benefited from automation. In this method, state-of-the-art technology like robots, machine learning (ML), and artificial intelligence (AI) take the role of human inspectors. To guarantee quality control in a timely, accurate, and cost-effective manner, automated inspection systems are playing an increasingly important role.

Automated inspection is changing several industries, including healthcare, electronics, and manufacturing. This blog will explain what it is, why it’s beneficial, and how it works. Anyone interested in technology, management, or running a company will find this guide helpful for understanding automated inspection systems and how to put them into practice.

Automatic Inspection: What Is It?-Automated Inspection

Using a combination of software, cameras, and sensors, “automated inspection” refers to the process of inspecting manufactured goods and their components for flaws before, during, or after manufacturing. These systems can perform various tasks such as measuring dimensions, searching for surface imperfections, and identifying defects, among other tasks.

Automated systems can work nonstop without getting tired, while human inspectors can only work for a set amount of time before they start to make mistakes.

Important Parts of Robotic Quality Control Systems-Automated Inspection

In most cases, the following elements work together to form automated inspection systems:

Cameras and sensors are devices that capture images or measure material properties such as size, pressure, and temperature. Visual inspection, 3D scanning, and infrared measuring are just a few examples of the many possible applications for these versatile tools.

Software: State-of-the-art software processes sensor and camera data using algorithms. In order to spot trends and outliers, this program frequently uses AI or ML models.

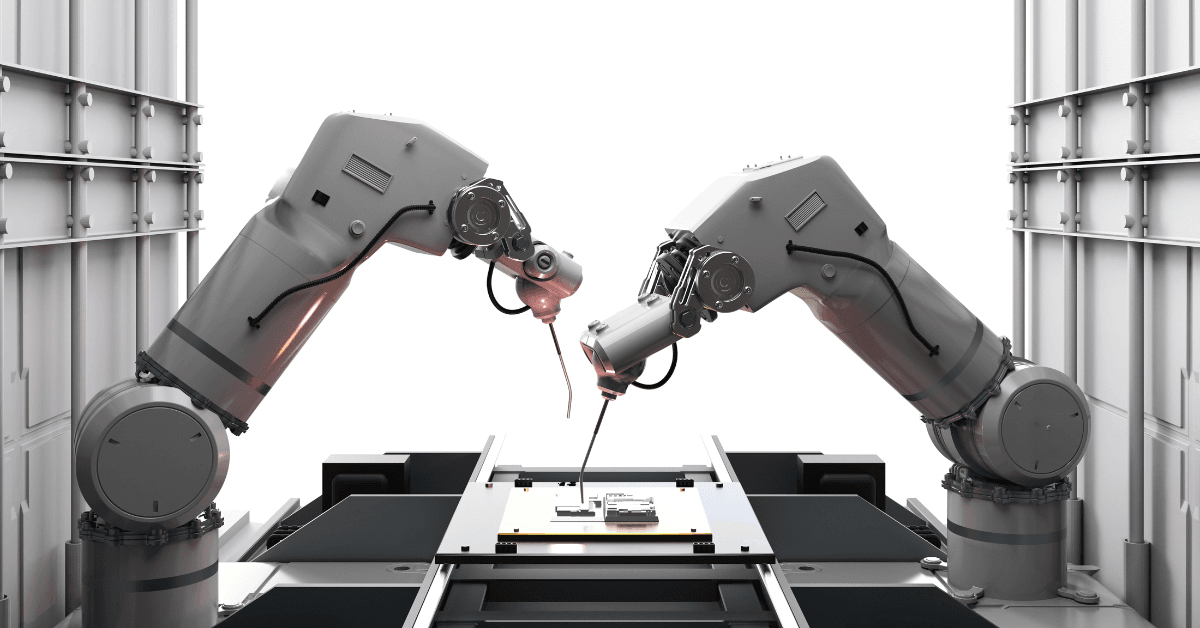

Robots and Actuators: Automation can physically handle products or examine them from different angles in some systems, allowing them to adapt to diverse inspection jobs.

Automated Inspection’s Advantages-Automated Inspection

1. Higher levels of precision and accuracy

Without the possibility of human mistake or exhaustion, automated inspection methods provide results that are both accurate and exact. They have the ability to identify flaws as minor as those that a human eye could miss. Industries like aerospace and automotive place a premium on this since even small flaws can cause major problems.

2. Both efficiency and speed have improved

Automated systems can run nonstop, unlike human inspectors, which allows them to complete inspections far more quickly. Increased throughput and decreased production times are crucial for organizations that want to stay ahead of the competition.

3. The Affordability

Despite their high cost, automated inspection systems yield long-term financial benefits. Less manual work is required, inspection errors are decreased, and product defects are minimized using these technologies, which means fewer returns and warranty claims. Another advantage of automated systems is their ability to maximize productivity at all times.

4. Maintaining a consistent, qualified standard

When it comes to inspections, automated systems guarantee that they are done consistently and thoroughly. Businesses are able to keep up their high standards and comply with regulations because of this consistency in quality control.

5. Gathering data in real time.

Instantaneous data collection is a key feature of automated examination. Businesses can find and fix problems more quickly with the help of these technologies since they give instant feedback on production quality. It is also possible to enhance operations and increase overall efficiency using this real-time data.

1. Automated inspection has several uses in the manufacturing industry

Manufacturing companies use automated inspection systems to monitor the quality of their products during production. Automated visual inspection devices, for instance, may spot surface flaws in electronic circuits, plastic components, and metal parts. Thanks to advancements in machine vision, it is now possible to accurately inspect thousands of parts every hour.

2. Electrical

Electronics manufacturers subject circuit boards and components to automated inspection to ensure their integrity. Misaligned components, soldering problems, and missing parts are among the most typical flaws found by automated optical inspection (AOI) systems. The electronics sector has very high-quality requirements, and these systems help keep them up.

3. Medical treatment.

To guarantee the high quality of surgical instruments, pharmaceuticals, and medical devices, automated inspection systems are indispensable in the healthcare industry. Automated inspection systems can detect flaws in pharmaceutical packaging, incorrect measurements in medical gadgets, and unclean surgical instruments. Accurate and efficient inspection methods are essential in this industry due to the rigorous standards.

4. Vehicles

The automobile industry uses AI as a tool to ensure the quality of manufactured cars. Robotic arms ensure correct component assembly, while visual inspection systems detect flaws in the bodywork. Automated technologies also employ tire alignment, welding joints, and component accuracy.

5. Consumables and drinks

The food and drink sector is one that is rapidly adopting AI methods to guarantee high-quality products. Vision systems can detect food contamination, and automated weighers can pack products according to rules. To ensure accuracy, these systems may also monitor when products expire and label them.

Difficulty with Automated Inspection:

1. Exorbitant Startup Expenses

One of the main barriers to using automated inspection systems is the large initial expenditure required. Particularly for SMEs, the costs of the technology, equipment, and installation can add up quickly.The upfront expenses may not be worth it to companies, but the ROI (return on investment) in the long run might be substantial.

2. Intricacy of Technology

A specific degree of technical knowledge is necessary for the implementation of AI systems. Businesses should provide their employees enough training to use and care for this equipment. It may also be necessary to make big changes to the infrastructure in order to add AI systems to current production lines.

3. Setting Up and Keeping Up

Maintaining accuracy in AI systems necessitates constant calibration. Regular maintenance can prevent system downtime. Over time, the systems may become less effective if they are not properly maintained, which could result in errors or system failures.

4. Lack of adaptability.

AI excel at simple tasks but may struggle with more complex assignments. Customized solutions may be necessary for certain industries or goods with distinct inspection requirements, leading to additional complexity and expense increases.

The Next Big Thing in Automated Inspection:

1. AI Integration

Combining AI with ML will be the wave of the future when it comes to AI. AI-powered systems can enhance system capabilities by continuously learning from previous inspections. The requirement for human involvement will diminish as these systems gradually gain greater autonomy.

2. Incorporating the IoT

It is believed that AI systems would rely heavily on IoT technologies. By establishing connections between inspection devices and the cloud, businesses are able to gain access to data in real time regardless of their physical location, remotely monitor system performance, and anticipate possible faults.

3. Robotics’ Expanded Role

More and more sectors will use robotic inspection systems as the technology behind them improves. Whether it’s inspecting intricate components or making manual tweaks during production, these robots will be able to handle complex tasks that demand flexibility. Additionally, robots can work in tandem with human operators to make the workplace safer and more productive.

Why should you finally use automated inspection?

It is of the utmost importance to maintain the highest quality standards while minimizing costs and maximizing efficiency in today’s globally competitive industry. To accomplish these objectives, AI is an effective tool for companies to use. AI systems, with their enhanced accuracy, speed, consistency, and real-time data, can revolutionize product inspection and keep companies at the forefront.

AI are a fantastic investment for any industry that wants to boost product quality, cut expenses, and streamline production. This includes healthcare, manufacturing, and more.

Urge:

Are you prepared to upgrade your quality control procedures with AI-powered inspection tools? Get in touch with us right now if you want to find out how state-of-the-art technology can transform your company and keep it competitive.

FAQ:

Automation inspection: what is it?

- Using digital or computer-aided systems to measure, analyze, and check parts for quality, accuracy, and compliance with requirements, automated inspection makes the process more efficient and consistent.

Which three primary categories of inspections exist?

- The three primary forms of inspections are functional (checking the product’s ability to carry out its intended purpose), dimensional (measuring size and tolerances), and visual (human or automated).

What distinguishes automated inspection from manual inspection?

- While automated inspection employs technology like sensors, cameras, or artificial intelligence (AI) to perform accurate, quicker, and more consistent evaluations, manual inspection depends on human skill and judgment.

Robotic inspection: what is it?

- Robotic inspection uses robots with sensors or cameras to do inspections, increasing accuracy, speed, and safety—particularly in places that are dangerous or difficult to access.

Automated board inspection: what is it?

- Automated board inspection improves quality control and manufacturing efficiency by checking printed circuit boards (PCBs) for flaws or irregularities using high-resolution cameras and algorithms.